Article info

28-07-2015, 08:26

- Views: 2440

- Author: vipsoft

- Date: 28-07-2015, 08:26

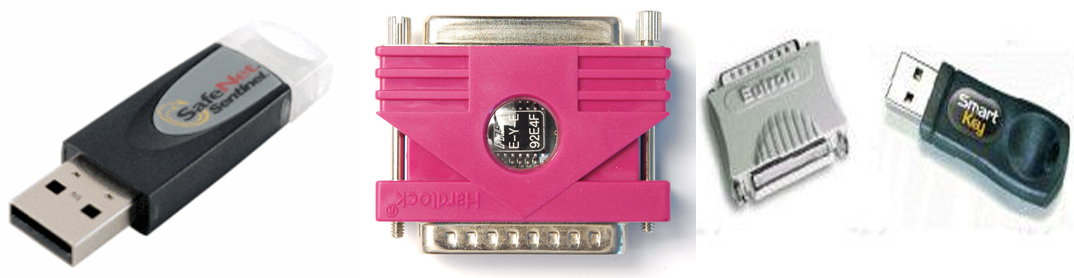

M&H 3D Form Inspect Software Smartkey Dongle

Category: Cad Cam

3D Form Inspect - the proven solution for your success. Measuring and quality control on the machine tool is gaining increasing importance in progressive manufacturing plants. This software enables quick, easy measuring and logging of important geometries and shapes on all sides and with all axes directly on the machine tool. This saves time, provides safety, and enhances quality.

Highest precision

m&h touch probe in conjunction with patented calibration ensures highest accuracy

One-time setting of triggering scatter during calibration

Vector calibration for high demands of speed and accuracy

Meaningful measuring protocols

Graphic representation of measuring results on the screen

Freely configurable display of results

Measuring protocol shown through Excel, Word, or HTML

Interface for linking up to other evaluation programs

Support of 4th and 5th axis

Measuring on all sides of the workpiece and at undercuts or inclined geometries in free space

Correction of kinematic errors on circular and swivelling axes

Maximum precision by patented compensation of swivelling errors

Collection of kinematic errors of the 4th and 5th axes through calibration or actual workpiece

Detected deviations are compensated for during the measuring process

Further functions

Support of cross/star probes

Use and management of several touch probes per measuring task

Management of measuring point groups using different on-screen displays

Touch probe configurator for all measuring tasks

Universal interface to job management system

Best Fit Function

Optimization of deviations in position and location by turning and shifting the workpiece

Can be used for quick fitting of the blank into the best machining position

Quick re-clamping of moulds for repair

Determination of position and zero point defining after measuring

Go Back

Comments: 0

Dear visitor, Our Softwares not FREE and all work with usb dongle if you interesting buy

Contact ME

Contact ME