Article info

21-03-2016, 10:57

- Views: 1418

- Author: vipsoft

- Date: 21-03-2016, 10:57

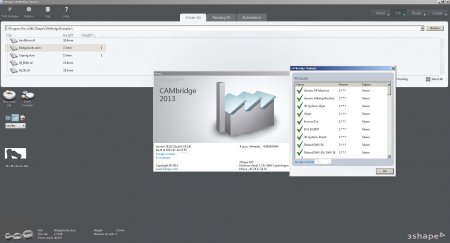

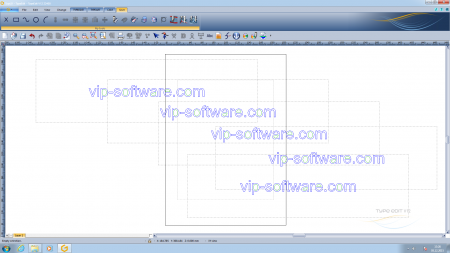

3Shape CAMbridge Dinkey Dongle

Category: Cad Cam

Making 3D printing easy

CAMbridge™ is designed for clinics and small- to mid-sized manufacturers without access to ShellManager™, optimizing your investment in 3D printers. CAMbridge™ removes much of the time-consuming work with managing print jobs.

Produce effortlessly

CAMbridge CAMbridge™ provides a complete interface to Rapid Prototype machines, optimized for automatic 24/7 production, and allows non-technical operators to streamline their workflows. Multiple printers can be assigned their own settings, styles and item management through a rich set of customization options.

CAMbridgeFast and easy to use

By simply clicking or drag & dropping items into Cambridge ™, the application automatically updates the build platform in the background. By utilizing multi-core processors, processing times are drastically reduced.

Article info

21-03-2016, 10:54

- Views: 1618

- Author: vipsoft

- Date: 21-03-2016, 10:54

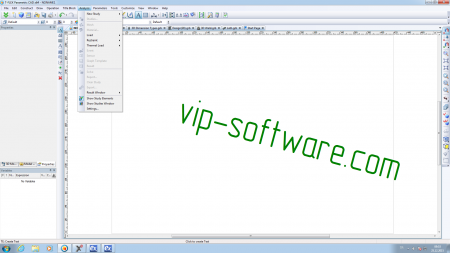

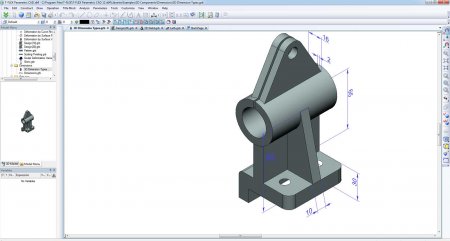

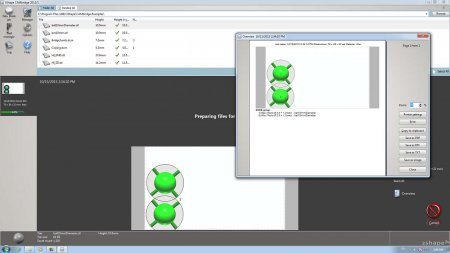

T-FLEX Parametrich CAD V12 English With Hasp Dongle

Category: Cad Cam

T-FLEX CAD is a full-function software system providing mechanical design professionals with the tools they need for today’s complex design challenges. It unites powerful 3D modeling functionality with the drafting and drawing production toolset.

T-FLEX CAD is an industry leading mechanical design system with flexible and intuitive workflow and superior design capabilities. The technical innovations and productivity advantages have made T-FLEX one of the most robust and versatile modeling and drafting solution for product development. Its extensive set of tools makes T-FLEX the best choice for meeting any professional challenge. T-FLEX is used extensively for everyday mechanical design applications including 3D/2D design, drafting, conceptual sketching, reverse engineering, tolerancing inspections, rapid prototyping, and downstream manufacturing.

Modeling Tools

T-FLEX modeling and assembly tools enable your engineering team to easily develop a full range of products, from single parts to assemblies containing thousands of components. T-FLEX harnesses the power of Parasolid® – production-proven modeling kernel developed by Siemens PLM Software. Highly innovative modeling tools allow designers to quickly create basic shapes and easily add common mechanical features like holes, rounds and chamfers, as well as more complex geometry such as draft angles, lofts, sweeps , three-face blends, and helical features.

Design Workflow

T-FLEX supports a simple unified mode of operations for all types of documents and entities: drawings, assembly drawings, solids, surfaces, parts, parts with multiple solid bodies, assembly models, sheet metal, bill of materials, etc. You use a common set of editing and data management functions on all types of geometry, streamlining workflow.

Parametrics and Adaptivity

T-FLEX cuts down design steps by making changes that propagate instantly throughout your design, incorporating superior design engines for adaptivity ands. This functionality helps you for example associate parts in a way that allows the change of one part to drive changes in associated parts. Any thing in T-FLEX can be related to anything else. Variables can be assigned at any time for component names, visibility, material, any numeric or text attribute of any entity. They can then be processed with any algebraic or logical expression to control the behavior of the design. The variables themselves can be changed manually by dragging entities on the screen, or typing values into the variable editor, or by reading ASCII or database files as assigned. Possibilities are endless and the interface is very intuitive. For this reason T-FLEX is a natural choice for family-of-parts manufacturers or any other design situations that use similar geometry but require many different sizes or permutations.

Parametric Drafting

Unlike other products, T-FLEX lets you create 2D drawings from scratch. The 2D CAD roots of T-FLEX are apparent when creating objects. When compared to most other solid modelers, even those focused on product design, T-FLEX has a much more robust palette of 2D tools, especially when it comes to drawing complex geometry. Its engine is the basis of T-FLEX design and unlike engines from other programs is not limited by the number of constrained 2D entities. T-FLEX drawing (parametric sketch for 3D operations) cannot be over or under defined. The drawing immediately updates to any changes regardless of their source. T-FLEX includes fully drawing documentation, including dimensions, tolerances, text, and drawing notes. You can create 2D assemblies by inserting 2D components with complex relations. The result can be fully automatic, so that a master drawing does not require any editing as changes are required. Constant re-documentation can be avoided through the use of the powerful documentations that are inherent in T-FLEX.

Creating Custom Dialog Boxes

Creating their own dialog boxes of model parameters directly inside T-FLEX users can control model in a very convenient and intuitive way. This unique functionality does not require any programming, programming knowledge or additional software installed.

T-FLEX is a Creative Tool

T-FLEX has one consistent characteristic for its history - its power is best utilized by the most creative designers. The interface is easy to learn and very consistent, but the real power lies in the incredible flexibility of design automation using functionality. From the beginning the goal was to provide engineers with access to creative design by giving them optimizing control over any aspect of the design process. The program’s Total Flexibility approach can truly eliminate redundant tasks and enhance design efficiency.

Assembly Modeling

T-FLEX easily tackles assembly 3D models that are fundamental to mechanical design. You can build complex assemblies consisting of many components using bottom-up design, top-down design, or a combination of both methods. Configuration management helps to simplify design reuse by creating multiple product variations within a single document. T-FLEX can simulate true motion and mechanical interaction between solids that allow you to avoid potential design flaws.

Adaptive Components

T-FLEX supports adaptive technology that allows creating assembly relationships by assigning geometrical links. With this you can capture design intent accurately, and manage and edit assemblies more easily.

Assembly Design Automation

Parametric connectors simplify assembly modeling by automatic parameter assignment for the parts being inserted. Parts location and sizes will adjust automatically on model modification. The structure of an assembly may be alterable. The drawings generated from a 3D assembly will update automatically on model modification with all detailing elements.

User-defined Features

The innovative technology of user-defined features substantially extends modeling functionality allowing users create their own modeling features. T-FLEX models may capture elements and geometry from other models as input parameters of operations inside their own model history tree. In that way any T-FLEX model can be defined as a special feature that will function equally with other modeling commands. This mechanism can dramatically reduce the modeling time providing users with the possibility of creating their own features and libraries of features for specific modeling tasks.

Deformation Commands

The set of deformation commands provide a simple way to change shapes of complex surface or solid models. Deformation may be applied either in a local area or globally. Various options may be specified by direct rules and parameters or via the special handlers. Fast preview based on input data is available prior to exact model generation.

Surfacing

T-FLEX synergistically combines solid and surface modeling enabling designers to extrude, sweep, revolve, and loft surfaces as can be done with solid models. It also enables to do things that can’t be done with solids alone. For example, a designer can draw lines or curves in space and fit surfaces between them, or add surfaces that blend between non-intersecting surfaces. Integrated surface and solid modeling provides flexibility in making design changes through the use ofs, constraints, and associative operations.

Direct Editing

T-FLEX supports direct editing of 3D models, retaining history of the edits so that they can be regenerated. This is very helpful for the imported models when there is no access to the original history tree. For example it is possible to modify parameters of the faces whose underlying surfaces are analytical (cylinder, cone, sphere and torus), as well as the parameters of faces created as blends. Other editing features include imprinting, face replacement, face extension, face removing, body separation, etc.

Detailing Features

Professional detailing functions support quick creation and complete manipulation of all common annotations used on mechanical drawings. T-FLEX contains an unmatched set of capabilities for the 2D documentation process, with excellent drawing layout, detailing, annotation and dimensioning controls that automatically comply with the mechanical drafting standard you select. Streamlined drawing creation T-FLEX automatically creates and updates drawings from 3D models, quickly creating standard and auxiliary views, including section, detail, broken and isometric views. T-FLEX provides flexibility and control of section views with improved control of the depth of a slice and selection tools that allow you to predefine components on a per view basis when creating section views. As changes are made to parts or assemblies, associated drawings update automatically. With T-FLEX, you have full control over every element of your drawings, so you know that they meet the requirements of organizational and international standards. Additional advanced capabilities, such as threaded connections, intelligent hatching of assembly sections, and accurate local sections, can significantly increase detailing productivity. T-FLEX’s associative detailing tools help avoid costly errors by preventing incorrect annotations from reaching production drawings.

Associative Bill of Materials (BOM)

T-FLEX can generate and update an accurate BOM in a fraction of the time required by traditional 2D methods. Part and subassembly quantities are always kept up to date, and are instantly organized and populated into a drawing BOM. Changes to the assembly (removing a part, for example) are associative, so the BOM table is updated automatically. BOM templates and table properties (column headings, sorting, title blocks, etc.) are fully customizable.

Integrated Sheet Metal Design

T-FLEX provides a set of commands tailored for the efficient construction of sheet metal parts from design of sheet metal components to flat pattern development and the creation of engineering drawings.

Mold Design

T-FLEX provides a sequence of integrated tools that control the mold creation process. You can apply body taper; generate parting lines and surfaces; resize the model's geometry to account for the shrink factor when plastic cools; perform tooling split to separate core and cavity. With the model finished, you can examine it for potential problems that might prevent the core and cavity from separating.

Express FEA

Built-in Express Analysis offers an easy-to-use first pass stress analysis tool that enables design engineers to execute design verification directly in T-FLEX. It helps to determine how designs will perform under real-world conditions, and identify potential design flaws before expensive physical prototypes are built. Express Analysis uses the same design analysis technology that professional FEA add-on module uses to perform stress analysis. More advanced analysis capabilities are available within the T-FLEX Analysis line of products.

Interactive Motion Simulation

T–FLEX provides a motion simulation solution for analyzing the complex behavior of mechanical assemblies. T–FLEX Dynamics allows you test virtual prototypes and optimize designs for performance, safety, and comfort, without having to build and test numerous physical prototypes. Results are viewable as graph, data plots, reports, or colorful animations that you easily can share with others.

Weldment Design and Documentation

T–FLEX lets you work in a weld-specific environment with functionality tailored to the unique design requirements of designing and documenting weldments. Model weldment annotations are associated with the model and automatically get updated when the model is changed.

Piping and Cabling Design

T-FLEX CAD includes design tools that automate routed systems design. It speeds up the process of routing tube, pipe, venting, electrical cable, and harnesses across various manufacturing industries and types of piping and cabling systems.

Open API

T-FLEX Open API is based on .NET technology offering customers and third-party developers extensive possibilities for developing add-on applications in various areas. T-FLEX’s set of entities can be extended with the custom objects. T-FLEX Open API supports full object oriented programming concepts and multiple programming languages with identical functional access to all T-FLEX functionality. It also helps users to customize T-FLEX for their specific environment and automate specialized workflows.

Product Manufacturing Information (PMI)

T-FLEX delivers the functionality needed to produce 3D-annotated designs to serve as single digital representations capturing all product information – reducing or eliminating the need for drawings in design reviews or manufacturing. Support for PMI technology allows the user to take established drawing dimensioning and annotation methods and take them to the 3D realm. It helps to generate a 2D drawing, extracting much of the vital detailing information automatically. It is also possible to modify a 3D model directly by changing the values of the 3D dimensions.

Parametric Engine for Internet

Using T-FLEX and T-FLEX Open API, third parties, OEMs, developers, and system integrators can deliver CAD functionality across a wide range of Internet-based products. T-FLEX utilized as an Internet engine, provides engineers, manufacturers and distributors with opportunity to display their products, use third-party designs and perform marketing activities.

Multilingual Support

T-FLEX is a Unicode application and hence supports all of the languages around the world. Unicode support in T-FLEX means that users can utilize multilingual text that will be displayed correctly in T-FLEX documents. There will be no problems with any language files names under any language version of Windows operating system. Users can name objects and parameters in whatever language they like.

Interface Flexibility

T-FLEX’s multiple interface options help maximize productivity by allowing users to choose an interface that matches their experience and preferences. The user interface is specifically designed to remove command clutter and operational complexity. The Windows-style pull-down menu interface is easy to navigate. Compact text-based command bar, icon toolbars and shortcut key assignments are also available. Enhanced capabilities, such as intelligent posi7tioning tools and pop-up menus driven by hot key activation, greatly simplify workflow. T-FLEX provides direct model interaction, using 3rd mouse button, dynamic geometry preview, and support for SpaceMouse® to seamlessly blend frequent and advanced capabilities.

Advanced Graphics Subsystem

High performance 3D graphics mechanisms ensure convenient operations even with very large assemblies. There is also possibility to generate high quality photorealistic images based on lighting and material properties such as transparency, refractive index, surface properties, etc.

Translators

The rich suite of T-FLEX translators enables you to satisfy differing import and export requirements, effortlessly. T-FLEX is interoperable with the most widely used 3D-modeling and 2D-drawing systems via the following formats: Parasolid, IGES, STEP, Rhino, STL, DWG, DXF, SolidWorks, Solid Edge, Inventor etc. Additionally, T-FLEX provides options for exporting graphical images to presentations, web pages, and other documentation.

3D Printing

With T-FLEX CAD you can print your models to 3D printers via STL, a widely accepted format, as well as other output formats. In addition to the model geometry, output file can contain information about the color of objects. You may customize the quality of the result using various parameters.

Article info

16-12-2015, 09:37

- Views: 4031

- Author: vipsoft

- Date: 16-12-2015, 09:37

Type3 TypeEdit v12 B

Category: Cad Cam

introduction to the V12 user interface

Discover a new modern interface including a Quick Access Toolbar (QAT), easier access to your tools, and an increased work area. All this and more…

A new work environment

Go through all steps of creation from logo vectorization to machining in this video. An interface with a simple yet functional and modern design, for a smoother workflow.

Logo creations with new symmetrical curves

New 2D sketching tools to speed up your design process.

Nesting and remaining material management

Create or import your pieces, use the Nesting menu to best adjust and optimise your nesting operation. Instantly visualize how the remnant plate feature can help you manage plate waste and cut costs.

Professional LED sign creations

Create professionnal LED signs using TYPE EDIT V12's new LED Matrix. Create your design and set all your parameters to optimize your creation and production.

Artistic 3D creation emphasizing on Construction tree

A new "S" shape sections for your TypeArt. This new type of profile adds flexibility and creative freedom for your bas relief creations.

Designing an insignia with revolved TypeArt

Efficiently and rapidly create revolved surfaces directly in TypeArt. Combine it with other tools such as Extrusion, Rotation, etc. for all your 3D productions

Automatic filling of holes in TypeArt

Correct your 3D imported surface files with this powerful tool. Holes will be filled automatically according to your parameters and allow a safer machining and finishing.

Tool choice support

Visualize toolpath and simulate tool combinations in seconds. And instantly apply your selection for safe and correct toolpath calculation.

Create and manage scripting

Create powerful scripts to automate processes. Keep full flexibility, deciding wether or not to display property menus.

Article info

25-11-2015, 12:50

- Views: 3722

- Author: vipsoft

- Date: 25-11-2015, 12:50

SCM WINCUT 12 Sentinel Hasp Dongle

Category: Cad Cam

SCM WINCUT

Control software for SCM-beamsaws

Attributes (2004)

Automatic mode to run programmes or programme parts

Semi-automatic operation for running up to 4 measures that are inputted by use of a keyboard

Multitasking

Graphical display of cutting patterns

Diagnostic system

Maintenance planning

Production report (production start and end, number of pieces, surface dimensions and solid measures)

Data import in the format Perfect Cut

Languages: Italian, French, English, Spanish, German

User interface: Manager

Options

Telesolve

3D simulation - for three-dimensional representation of the cutting cycle

Graphic editor - aids for creation of cutting plans

Labeling

Easy Cut, Easy Cut Plus, Easy Cabinet

Cutting plan optimization (Cutty, Cutty Plus, Cutty Office, {Ottimo Perfect Cut;10953)

Article info

25-11-2015, 12:43

- Views: 1564

- Author: vipsoft

- Date: 25-11-2015, 12:43

CAMbridge 3Shape Dinkey Dongle

Category: Cad Cam

Making 3D printing easy

CAMbridge™ is designed for clinics and small- to mid-sized manufacturers without access to ShellManager™, optimizing your investment in 3D printers. CAMbridge™ removes much of the time-consuming work with managing print jobs.

Produce effortlessly

CAMbridge CAMbridge™ provides a complete interface to Rapid Prototype machines, optimized for automatic 24/7 production, and allows non-technical operators to streamline their workflows. Multiple printers can be assigned their own settings, styles and item management through a rich set of customization options.

CAMbridgeFast and easy to use

By simply clicking or drag & dropping items into Cambridge ™, the application automatically updates the build platform in the background. By utilizing multi-core processors, processing times are drastically reduced.

Article info

25-11-2015, 12:41

- Views: 1210

- Author: vipsoft

- Date: 25-11-2015, 12:41

Framecad98 Uzay Çatı Sistemi

Category: Cad Cam

Article info

25-11-2015, 12:34

- Views: 1382

- Author: vipsoft

- Date: 25-11-2015, 12:34

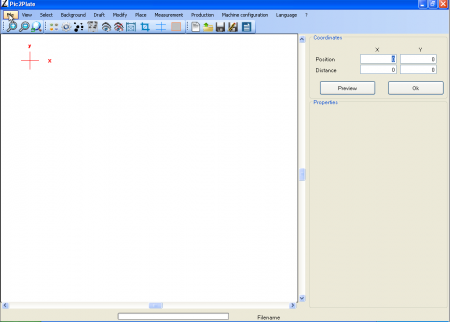

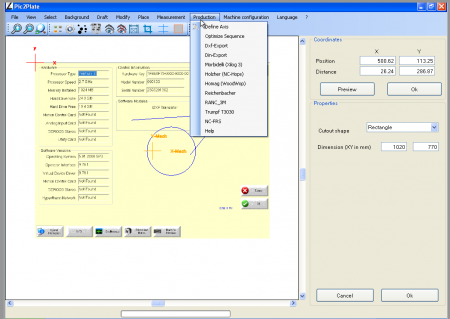

Pic2Plate Usb Custom Dongle Full modul

Category: Cad Cam

Beschreibung

Pic2Plate ist ein von uns erstelltes Produkt zur Erzeugung von Gravuren auf Laser- Stanz- und Fräsmaschinen.

Schwerpunkt der Software ist die Realisierung von Bildgravuren wie Sie von speziellen Gravurlasern oder Graviermaschinen erzeugt werden.

Dazu wurden mehrere Funktionen realisiert:

1. Automatische Gravurerstellung

2. Erstellung von Schriftgravuren

3. Erstellung von Stanzmustern

Für die automatische Gravurerstellung stehen mehrere, unterschiedliche Automatismen zur Verfügung.

Die einzelnen Algorithmen sind auf die verwendete Technologie abgestimmt. Bei diesen Berechnungen wird die Bildvorlage mit einer hinterlegten Farbtabelle verglichen. Die Umrisse werden nicht als solche erfasst und nachgezeichnet, was Pic2Plate von den handelsüblichen Programmen grundlegend unterscheidet.

Aktuell wurden Berechnungen für Laser-, Plasma, Fräs- und Graviermaschinen realisiert. Die Details zu den jeweiligen Lösungen finden Sie im entsprechenden Abschnitt.

Beim Nachzeichnen entstehen Bilder indem einzelne Konturelemente als Linien und Bögen nachgezeichnet werden. Dabei kann das Bild als Hintergrund geladen werden um die Konturen nachzuempfinden. Weitere Details hierzu finden Sie unter "Zeichnen".

Die Erstellung von Schriftgravuren gehört in den Bereich "Zeichnen". Hierbei kann jede auf dem Rechner installierte True-Type-Schriftart verwendet werden. Die Umrisse des eingegebenen Textes in der gewählten Schriftart können hiermit graviert werden. Da dies eine häufig angefragte Anwendung darstellt haben wir diesen Punkt hier separat aufgeführt. Weitere Details finden Sie unter "Schriften".

Die Erstellung von Stanzmustern erfolgt automatisch durch einen speziellen Algorithmus. Auch hierbei wird die Bildvorlage als Lochmuster umgesetzt. Dabei kann zwischen runden und quadratischen Löchern gewählt werden.

Speziell für Stanz- und Nibbelmaschinen können hier die Lochdurchmesser nicht nur automatisch errechnet werden. Es ist auch möglich bis zu 8 Werkzeugdurchmesser zu definieren, die für die Erzeugung des Bildes verwendet werden sollen.

Schnittstellen

Pic2Plate kann folgende Bildformate lesen: *.jpg;*.png;*.jpeg;*.gif;*.bmp;*.emf;*.tif.

Die erzeugten Konturen sowie das bearbeitete Bild kann in einem speziellen Format (*.p2p) zur späteren Weiterverarbeitung gespeichert werden.

Darüber hinaus steht eine dxf-Schnittstelle zum Austausch mit anderen Systemen zur Verfügung.

Um für den nötigen Komfort sorgen zu können, besteht die Möglichkeit einen speziellen, an Ihre Maschine angepassten Postprozessor zu implementieren. Damit können NC-Texte generiert werden, die direkt an der Maschine geladen werden können. Da hierbei in der Regel Anpassungsbedarf besteht wird der Postprozessor vorab vorbereitet und an der Maschine in Betrieb genommen.

Bereits realisiert wurde z.B. ein Postprozessor für eine Morbidelli-Fräsmaschine mit XILOG3, sowie Postprozessoren für Reichenbacher, Homag, Holzher (NC-Hops), sowie ein allgemeiner DIN-Postprozessor.

Bildvorbereitung

Oftmals werden die Bilder in falscher Ausdehnung geliefert oder sind so groß, dass diese auf mehrere Platten verteilt gefertigt werden sollen.

Aus diesem Grund wurden Funktionen realisiert, um die Bildgröße anzupassen oder Bilder in mehrere Teile zu zerteilen. Da dies bereits Umfang der Demoversion ist können Sie dies gerne selbst testen.

Hilfe

Die Hilfedateien sind als PDF realisiert und werden mit dem Programm installiert. Bei Fragen zur Anwendung senden Sie doch bitte eine Mail an info@lettnerworx.com.

Lizenz

Die Lizenzierung erfolgt Rechnerbasiert. Eine erworbene Lizenz ist nur für den jeweiligen Rechner gültig.

Generell sind unsere Lizenzen zeitlich nicht limitiert.

Innerhalb einer Version müssen Entwicklungen nicht neu gekauft werden. Die Entwicklungskosten fallen somit innerhalb einer Version nur 1x an.

Die Preise für die einzelnen Module erhalten Sie auf Anfrage oder in der Preisübersicht. Aufgrund der Modularisierung ist der Preisübersicht nicht immer eindeutig zu entnehmen welche Lizenzen benötigt werden um das gewünschte Ziel zu erreichen. Daher beraten wir Sie gerne um zu einem optimalen Ergebnis zu kommen.

Article info

14-10-2015, 08:39

- Views: 2838

- Author: vipsoft

- Date: 14-10-2015, 08:39

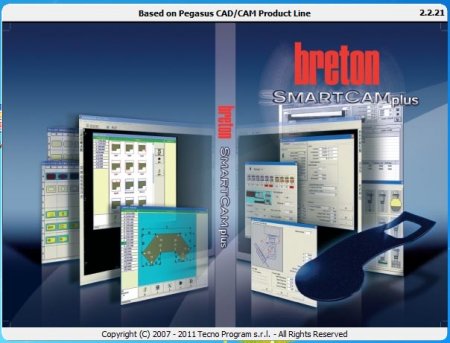

Breton SmartCAM 2.2.21 Pegasus Cad-Cam Sentinel Hardware Key

Category: Cad Cam

Article info

8-10-2015, 13:01

- Views: 1686

- Author: vipsoft

- Date: 8-10-2015, 13:01

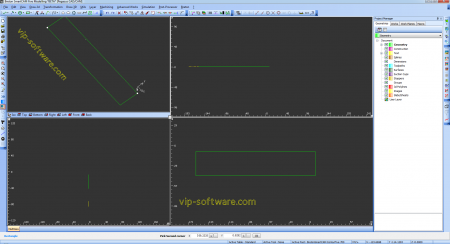

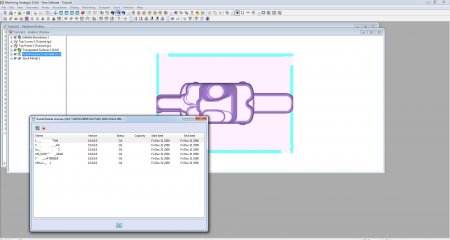

Machining STRATEGIST ( FlexLM License ) don't need Crack

Category: Cad Cam

Machining STRATEGIST

Take your machining productivity to new heights

Machining STRATEGIST is a powerful 3D CAM product that generates optimum roughing and finishing CNC toolpaths from the complex shapes generated by all major 3D modelling systems. With demands for ever-shorter lead times and improved quality, High Speed Machining (HSM) is now common place in many mould, tool and die shops both in the CAD/CAM office and on the shop-floor to machine hard materials with increased feed rates.

Machining STRATEGIST is a technological leader in this area with many unique machining strategies for generating world-class machining programmes. At the same time, many of these strategies can improve the productivity of older CNC machines with dramatically reduced air cutting time and programmes with smooth arcs which help to maintain continuous machine tool motion.

Installed in a CAD/CAM office or on the shop-floor, Machining STRATEGIST can take your machining capabilities to new levels and productivity to new heights.

Features at a glance:

Smooth motion control machining for all toolpaths

Tooling libraries, incorporating toolholders

Toolholder gouge protection

Drilling

Taper cutter support

3+2 axis machining

Rest machining, including rest roughing and transversal rest finishing

Flat surface machining

Steep/shallow machining option for all 3D toolpaths

Variable stock-allowance to steep and shallow areas

Batch processing, Multi-threading processor support

Calculate multiple processes simultaneously in one database

User Interface

Machining STRATEGIST has been developed to be very easy to learn and use and training is typically only one to two days in total. The software has context sensitive menus and dialog boxes and is intuitive to drive, while many parameters are calculated automatically or remembered to minimise operator input. Operations are driven from a browser-like tree structure that develops to show the history of the job.

On-line help

The on-line help contains comprehensive and easy to understand text and illustrations while every effort has been made to ensure that it is written in plain English. The help is fully context sensitive and displays topics relevant to the current operation and dialogue box. Hyperlinks have been incorporated to guide the operator towards useful related topics, making the online help intuitive and easy to navigate. Reading third-party data accurately is critical to the successful operation of a stand-alone CAM system. IGES 3D surface and solids data can be read in to Machining STRATEGIST together with VDA-FS, STL or direct CATIA interface. An optional native Parasolid reader allows the transfer of Parasolid files from VISI Modelling or other Parasolid-based modellers. Machining STRATEGIST can export STL files, which can be particularly useful after applying fillets to a model.

Multiple Machining Strategies

The range of machining options available within Machining STRATEGIST includes:

Drilling

Z-Level Roughing

Core Roughing

Lace Roughing

Adaptive Roughing

Rest Roughing

Horizontal (Flat Surface) Finish Machining

Z-Level Waterline Machining

Raster (Planar) Machining

Radial Machining

Spiral Machining

Morph Machining

Along Boundary (Scribe) Machining

Axial Offset Machining

3D Constant Offset Machining

3D Corner Offset Machining

Pencil Milling

Parallel Pencil Milling

Transversal Rest Machining

All machining options have techniques for maintaining constant machine tool motion - an essential requirement for maintaining higher feedrates and eliminating dwelling, the single worst contributing factor to tool wear. Any 3D machining strategy, can be controlled by specifying the surface slope-angle to be machined, without the need for steep/shallow boundaries. This means that, in addition to water-lining steep areas, shallow areas can be machined using any of the remaining 3D machining strategies. So a radial part could be finished with a combined steep waterline and shallow radial strategy. All toolpaths in Machining STRATEGIST are created as a two-step process:

(a) Toolpath passes are generated, calculated to a particular tool and tool holder.

(b) Toolpath passes are linked with a home position, rapid moves and toolpath linking moves.

There are a number of inherent benefits to this approach. Firstly, if a different linking strategy is required, it is not necessary to recalculate the original toolpath passes. Secondly, if the original toolpath passes require editing, this is done prior to the linking stage resulting in more control and better linking of trimmed toolpaths. Toolpath linking moves were designed to minimise the time the cutter is spent off the job with the net effect that overall machining times are reduced. All machining strategies can be driven in a 3 2 axis orientation. Machining STRATEGIST in 3 2 axis mode is as straightforward as conventional 3-axis machining with 2D boundaries created in 3D space determining the Z-axis machining orientation, which can be set as an AB, AC or BC rotation depending on the particular machine tool setup. Whether machining with a high speed or conventional machine tool, Machining STRATEGIST can help to reduce overall machining times while improving tool life and providing better machine tool motion.

Part Analysis

State-of-the-art graphics are used to maximise the visual aspects of Machining STRATEGIST. Once read in, imported CAD data can be viewed as wire-frame, wire-frame with hidden-line removal or fully rendered and fully rendered with surface edges drawn. Use of OPEN-GL graphics facilitates real-time dynamic rotation, zooming and panning. Machining STRATEGIST has a variety of interactive tools for analysing the part geometry. By snapping to surface node points accurate measurements can be taken including :

Dimensions

Lengths

Surface Curvature

Slope Angle

Any surface can be viewed at a vector normal to itself and this is particularly useful when positioning the part for 3 2-axis machining.

Fillets

A dynamic sectioning function allows for closer interrogation of cross sectional detail. This can be useful when analysing toolpaths which might otherwise be obscured by steep wall areas or for visually viewing the difference between a remaining material stock model and the finished component. A minimum curvature can be assessed on parts relative to the smallest cutter to be used. By inputting the minimum cutter radius, a new model is generated detailing corners sharper than the specified cutter. Fillets can be used to smooth out the model for machining. Standard radius fillets can be created slightly larger than the ball-cutter to be used. The result will be machining that has continuous movement and no dwelling. Fillets can also be specified to have a different radius to the diameter and this can be useful if 3-axis machining with carbide-insert button cutters. As an example, if machining with a 32r6 cutter, fillets of 34r7 could be created, resulting in smooth, continuous machining even in what were previously sharp internal corners. Fillets are generally produced in seconds, even on large detailed models. With the use of fillets, smooth machine tool motion, better surface finish and improved tool life are assured. Models read in with open hole details can be filled with Machining STRATEGIST, using the planar patch facility, in most cases eliminating the need to take the part back in to a modelling system for modification. Planar surfaces can be modelled if the component is destined to become a core or electrode. If planar holes are located at a vector in space, these can also be filled, by specifying an AB rotation for the boundary used to constrain the planar patch. Machining STRATEGIST automatically looks down the vector path the boundary is created in when performing any associated command such as machining or in this case, creating a planar patch.

Batch Processing

The history-tree structure within Machining STRATEGIST can be used to record a sequence of events. Rather than recording a macro in advance, the user can selectively specify exactly which machining sequences to record after the operation has been run. This allows the user to build up a selection of operations which can be used to automate other jobs. For instance, a sequence of roughing and rest-roughing operations could be recorded using particular cutters for small, medium and large parts.

User-definable Profiles

Within a session of Machining STRATEGIST, the operator can specify the software to retain any values which have been input / overridden. When exiting Machining STRATEGIST, the operator can then save this session as a Profile. Profiles work especially well for different sized components, different operators who wish to work in their own particular style and even different machine-tools, since high speed machine tools benefit from different default parameters to conventional CNC's. Used in conjunction with batch processing, User-definable Profiles can help to make the most of process automation.

Roughing

Machining STRATEGIST's roughing routines employs a number of techniques which, when combined, results in a program with the smoothest cutting motion and significantly enhanced tool life: A series of offset passes are generated at specified Z-depths and are automatically calculated to remove the maximum amount of material without leaving upstands. The depth of cut automatically adapts, ensuring that flat faces are machined to within the prerequisite stock allowance. A Core Roughing strategy is optimised to machine from the outside-in, resulting in better cutting conditions when machine cores or parts with upstands. Upon linking the passes, an "effective cutting diameter" helix entry is calculated, completely machining the material under the cutter as it moves to its next Z-depth. Cutter contact is maintained as much as possible to avoid the reduction of tool life. Machining STRATEGIST automatically adapts to a profile ramping condition following the toolpath as the tool ramps down in Z if a helix entry is not possible. If both a helix entry or a profile-ramp entry would leave material under the effective cutting diameter of the cutter, which might result in the cutter being damaged as it drops deeper in Z, Machining STRATEGIST discards this part of the toolpath, to be picked up later by a rest-material re-machining operation. The software cannot plunge vertically down the tool-axis, ensuring safe, reliable cutting conditions at all times. Smoothing arcs are created automatically, eliminating dwelling, improving effective cutting feedrates and tool life. Smoothing arcs are also generated on the most critical pass, where the cutter is in contact with the workpiece stock allowance. Linking moves, from one offset profile to the next, are created with smoothing arcs to maintain a more constant cutting motion Machining STRATEGIST fully gouge protects for not just the tool but also the toolholder. For older machine tools and machining softer materials, a traditional lace-roughing toolpath is available.

Stock Models and Rest Roughing

A stock model can be created and used to reference a cutter with greater reach to re-machine areas the previous tool could not machine due to potential toolholder interference. Machining STRATEGIST can rest machine to either a 2D or 3D stock model. 2D stock models are used to build up a series of "slices" from roughing operations which can then be used to rest-rough against progressively smaller cutters. A hybrid toolpath, which profile machines and area clears only where required is automatically generated. 3D stock models can be used in a similar capacity but can be more useful when rest machining at a semi-finish machining stage, for Cast Machining or to purely visualise a composite sequence of machining operations. Since accurate rest roughing toolpaths can become more fragmented, tight control is maintained over the rapid linking moves. This happens with little or no operator intervention since the defaults are set up to function in this fashion automatically. In many cases, the cutter remains deep inside the workpiece when making rapid moves from one cut pass to the next. The result is less air-cutting time and greater productivity.

Toolholder Gouge Protection

Toolholders can be specified from a standard tooling catalogue or be created according to any toolholders available in the customers shop. These can then be stored in a database, accessible over a network if required. There is no limit to the complexity of the toolholder which can be created. The primary benefit of specifying a toolholder is that, by using short, rigid roughing cutters, large cavities can be roughed out more efficiently by maintaining a greater depth of cut and higher feed rates. As the holder clears the surfaces, the tool can clear out to depths far greater than the actual tool length. Toolholder gouge protection aids in 3 2 axis machining operations since the software will allow the operator to machine areas which might be deemed as otherwise inaccessible unless using this approach. By specifying the toolholder shape, all toolpath calculations will be fully gouge protected including the leading and trailing edges of the defined toolholder.

Boundaries

Boundaries can play a major role in semi-finish and finish machining since it is rare that a carbide cutter can machine a complete die steel block without being replaced, so it often becomes necessary to isolate local areas to be machined. Machining STRATEGIST has a comprehensive set of boundary creation and modification tools, including:

Silhouette Boundaries

Contact Area Boundaries

Shallow Boundaries

Theoretical Rest Area

Boundaries from cutter path passes

Freeform

Rectangle

Circle

From Text (True Type Fonts)

Editing Toolpath Passes

Any set of toolpath passes can be trimmed back to a boundary, or set of boundaries, created in any 3D plane. Toolpath passes can also be edited to stock models and original models. In addition, toolpath passes can also be edited to a toolholder. In operation, a set of toolpath passes can be created without a toolholder. These passes can then be edited to a toolholder whereby the minimum tool length can be established. A complete 3D toolpath can be split into zones based on tool length, with shorter tools being utilised to maintain rigidity, with faster feed rates, followed by longer, less rigid tools with appropriately reduced feedrates.

Linking

Machining STRATEGIST linking options are designed to keep the cutter in continuous motion and to minimise the time the cutter spends off the job. When roughing and horizontal machining, linking moves are designed to have smoothing arcs and for the cutter to keep in contact with the part for as long as possible. For waterline passes, the default is to keep the cutter in contact with the part as it moves from one Z-level down to the next. If the cutter has to leave the surface to enter at another cut position it will do so with arcing movements. With rapid moves, the default is for shortest route rapids which look ahead at the surfaces/ stock model and take a "racing-line" approach to the next cut move. For all other machining operations, similar approaches are used. While excellent for HSM, these moves can be demanding for older and slower controllers so a second option, minimum vertical retracts can be enabled to still keep the cutter in the part as much as possible. Finally, there is a full vertical retract option which forces the cutter back to a minimum safe Z height. Within all linking options, arc moves maintain continuous machine tool motion.

Sister Tooling

There are two methods of generating sister tooling toolpaths whereby an identical replacement tool is on-hand to replace the current tool after a period of use. The first allows the operator to force a retract every N mm. This has been designed to force a retract on older machine tools which may not have a tool-changer or where the operator only requires a retract move to manually change the cutter or to facilitate an insert change/rotation. The second works from a linked toolpath. It will split the linked toolpath into a number of new toolpaths each with a home position. The operator can specify a linear distance or number of tools to be used. Tool changes will always occur at the end of a cut pass to minimise any marking of the workpiece.

Tooling Sheets

Machining STRATEGIST takes advantage of Internet Explorer to display tooling sheets which can be viewed as an HTML document on any suitable computer within a company's internal network, providing a paperless means of distributing tool sheets. Tooling sheets contain comprehensive information and graphics with hyperlinks to the actual tape file itself. If printouts are required, a more simplistic tooling sheet can be produced without graphics.

Post Processors

Standard with Machining STRATEGIST, including configurations for the latest machine tool controllers. These postprocessors, if required, are easily configurable by the operator.

Article info

8-10-2015, 12:58

- Views: 2991

- Author: vipsoft

- Date: 8-10-2015, 12:58

Biesse Bsolid 2.5 Hasp Dongle

Category: Cad Cam

bSolid is the NEW, innovative software from Biesse that allows any user to go from a concept to visual design of a part in just a few clicks. bSolid is fully integrated with the machine allowing you to know in advance what will happen when the program runs, reducing costly errors. bSolid incorporates a new learning system that transforms your imagination into reality, guaranteeing simplified process management, improved performance and reduced machining times.