Article info

28-07-2015, 08:26

- Views: 2404

- Author: vipsoft

- Date: 28-07-2015, 08:26

M&H 3D Form Inspect Software Smartkey Dongle

Category: Cad Cam

3D Form Inspect - the proven solution for your success. Measuring and quality control on the machine tool is gaining increasing importance in progressive manufacturing plants. This software enables quick, easy measuring and logging of important geometries and shapes on all sides and with all axes directly on the machine tool. This saves time, provides safety, and enhances quality.

Highest precision

m&h touch probe in conjunction with patented calibration ensures highest accuracy

One-time setting of triggering scatter during calibration

Vector calibration for high demands of speed and accuracy

Meaningful measuring protocols

Graphic representation of measuring results on the screen

Freely configurable display of results

Measuring protocol shown through Excel, Word, or HTML

Interface for linking up to other evaluation programs

Support of 4th and 5th axis

Measuring on all sides of the workpiece and at undercuts or inclined geometries in free space

Correction of kinematic errors on circular and swivelling axes

Maximum precision by patented compensation of swivelling errors

Collection of kinematic errors of the 4th and 5th axes through calibration or actual workpiece

Detected deviations are compensated for during the measuring process

Further functions

Support of cross/star probes

Use and management of several touch probes per measuring task

Management of measuring point groups using different on-screen displays

Touch probe configurator for all measuring tasks

Universal interface to job management system

Best Fit Function

Optimization of deviations in position and location by turning and shifting the workpiece

Can be used for quick fitting of the blank into the best machining position

Quick re-clamping of moulds for repair

Determination of position and zero point defining after measuring

Article info

28-07-2015, 08:15

- Views: 3139

- Author: vipsoft

- Date: 28-07-2015, 08:15

Kaledo Style V3R3 Technical Fashion Design

Category: Cad Cam

Learn more about Lectra’s technical design solution, Kaledo Style. Easy-to-use, apparel-specific tools give designers the power to create new styles and carry over bestsellers to achieve reduced development time. Kaledo’s sketching and boarding tools go beyond simple flat sketches to create complete production-ready technical packs and ensure that garments are produced correctly

Article info

28-07-2015, 08:08

- Views: 3474

- Author: vipsoft

- Date: 28-07-2015, 08:08

SEE Electrical Expert V4

Category: Cad Cam

The "Concurrent Engineering" module is a powerful solution for multiple designers to work collaboratively on the same project.

• "3D Panel" supports designing electrical installations in 3D and offers a realistic view of equipment and their physical positions as well as space requirements, visualization and collision control.

• From the installation diagram, the "Synoptic" module automatically generates all the terminal strips and cables and updates the schematics.

• The "Harness Documentation" module is an intuitive and easy-to-use tool for designing 2D harnesses and routing the wires and cables in accordance with the schematics.

• Multiple ways to configure machine or electrical installations and to automatically generate a complete electrical project (schematics, terminals, part lists, cable lists, etc.) from:

- an Excel spreadsheet

- CompoData, the IGE+XAO Group software suite to configure more complex systems.

Several communication gateways with other software packages :

- Mechanical CAD (Catia, SolidWorks, Creo, NX, Inventor AutoCAD,etc.),

- PDM (SmartTeam, Windchill, TeamCenter, SolidWorks ePDM…),

- ERP (SAP…),

- or other professional software (PLC, programming, labelling, panel manufacturing, cable cutting, documentation, archiving, cost calculation, etc.) promote the integration of SEE Electrical Expert "Control Package".

• SEE Electrical Expert "Control Package" exchanges information with PLC programming software in order to automatically generate and update Input/Output card layouts. This functionality is particularly optimised for SCHNEIDER Electric’s Unity Pro as SEE Electrical Expert "Control Package" has direct access to the heart of this platform.

• Document exchanges are easy thanks to numerous graphical interfaces (PDF, DXF, DWG, JPEG, TIFF, WMF, etc.). XLS, XML, ASCII, etc. interfaces also supports export or import of data.

• Partnerships with major electrical equipment manufacturers (ABB, Legrand, Eaton - Moeller Electric, Phoenix Contact, Rockwell Automation - Allen Bradley, Schneider Electric, Siemens, Socomec, Wago, Weidmüller…) provide the largest catalogues in the market with more than 700,000 parts.

• 100% unicode, SEE Electrical Expert "Control Package" V4 supports all kinds of alphabets.

A complete environment for an immediately operational business package:

• more than 1,000 electrical standardized symbols (IEC, IEEE,etc.),

• more than 700,000 parts available online through our web server,

• many design templates built in (motor starters with corresponding control part, drives, PLC cards, etc.),

• over one hundred reports templates lists configured which can be customised,

• dozens of part list templates,

• hundreds of working methods available (symbol tagging, wire numbering formats, terminal strip layouts, connectors, cables, management of interconnections, part list templates, terminal and cable lists, XLS and XML export formats…).

Article info

28-07-2015, 08:00

- Views: 4046

- Author: vipsoft

- Date: 28-07-2015, 08:00

Metalix MBend 3.5.148

Category: Cad Cam

MBend bending program is a comprehensive solution for CNC Press Brakes, facilitating bending of Sheet Metal Parts.

It loads an existing drawing, calculates bending sequence, suggests the tools and back stops to use, and produces the NC program.

Benefits:

Offline programming decreases machine down-time

Achieving reliable programs with fewer experts on-hand

Improved fabrication quality thanks to better production planning

Increased production avoiding costly errors, with Collision Detection

Integration with other Metalix products such ascncKad and MetalixUnfolder

User friendly

What does it do?

Imports parts as a 3D Model or as a 2D DXF

Allows Bend Sequence Selection

Enables Automatic Tool Selection

Allows Automatic Fingerstop Positioning

Runs 3D Bending Simulation with Collision Detection

Generates NC programs in native controller format (Delem, Cybelec, Amada, etc.)

Creates detailed Manufacturing Reports

MBend works with all press brake makes and models and with any controller.

3D simulation

MBend comes with real-time, automatic 3D Simulation, presenting you realistic visualisation of Bending process. The purpose of a simulation is to create an error-free job so that you can output the relevant NC codes or a Bending Report.

The simulation lets you check whether the part collides with the press brake, tool setups, finger-stops, or even with itself. It also checks whether the finger-stops collide with any of the tool setups, and whether the punches collide with the dies.

While simulating you can manipulate the display and see the process from the best angle possible.

Benefits:

Real-time animation

Realistic visualization of bending process

Dynamic collision analysis (e.g. backgauge movement)

Detection of collisions between all moving elements

Operator part handling

Program 100% correct

Article info

17-02-2015, 15:02

- Views: 2319

- Author: vipsoft

- Date: 17-02-2015, 15:02

Shoemaster 14.03 Hasp SRM Dongle

Category: Cad Cam

Article info

16-02-2015, 12:39

- Views: 2193

- Author: vipsoft

- Date: 16-02-2015, 12:39

Gps.Opt Optimization 7.62

Category: Cad Cam

Focusing on wastage results alone reserves GPS.opt the top position in the industry’s software solutions. GPS.opt also allows a seamless integration into the production control software and the associated benefits of using a range of perfect planning tools to layout the cutting schedule. This secures a competitive edge for your company.

In combination with TSO – the first true shape optimizer, GPS.opt increases the potential to save material and therefore money.

With GPS.opt you can decide to use A-racks or harp cars to stack the glass after cutting. The stacking method makes no difference to the system.

The stock plate editor allows the operator to modify the optimization and add new sizes manually or insert remakes to avoid wasteful remnant sheets. Normal optimizers surround shapes with a rectangle to allow breakout, but this increases the wastage enormously. TSO however integrates the shapes together, which reduces the waste significantly. The degree of nesting can be selected using parameters in GPS.opt, but the system automatically generates help cuts to aid the breakout of complex shapes.

“DXF, CAD, CNC”, these technical words are part of the GPS.opt vocabulary. Using these standard interfaces GPS.opt can receive geometric code and convert it into control code to directly run cutting tables, glass loading systems.

Highlights

Waste Reduction

Easy Order Entry

Automation

Integrated CNC Code Converter

Compatibility

DXF Interfaces; Link to the Order Entry (Order Transfer)

Edge Deletion of Stepped Units

Consideration of Grinding Addition

Article info

9-01-2015, 10:12

- Views: 4902

- Author: vipsoft

- Date: 9-01-2015, 10:12

Metalix CncKad V12 Hasp SRM DONGLE

Category: Cad Cam

Article info

21-11-2014, 09:01

- Views: 4492

- Author: vipsoft

- Date: 21-11-2014, 09:01

HPO Improvement Optimisation - Schelling Sentinel Hasp SRM Dongle

Category: Cad Cam

HPO Improvement

Optimisation of the cutting plan is the key element for maximum material usage. In this training module we turn participants into experts in the field. This increases the efficiency of production and viability of the machine.

Content

Parts list entry

Learn how to enter parts lists and how to import data.

Panel entry

Enter boards in the data base or, in the case of boards related to parts lists, in the parts list.

Optimisation

Start optimisation and detect and rectify potential errors.

Results

Find out how to simply export and print the results of the optimisation.

Transmission

Learn how to send the optimised process to the machine online.

Article info

31-10-2016, 10:48

- Views: 1726

- Author: vipsoft

- Date: 31-10-2016, 10:48

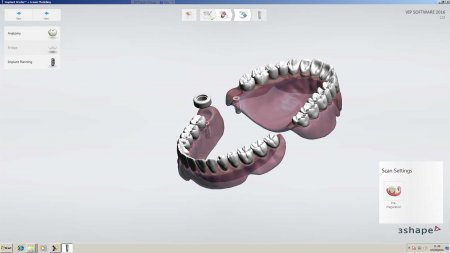

3Shape Implant Studio Dinkey Dongle

Category: Cad Cam

3Shape Implant Studio®

Dental labs and practices use 3Shape Implant Studio® for prosthetic driven implant planning and surgical guide design. Implant Studio® introduces digital accuracy and predictability, while improving patient experience.

Implant Studio creates a simplified and predictable top-down digital workflow for implant procedures. It enables the digital planning of single to complex implant procedures by considering the esthetics and intended final restoration as well as the overall clinical situation. Professionals can also use Implant Studio to cost-effectively create, print and mill their own surgical drill guides.

Dentist, Dr. Philip Tan from Australia says, "Implant Studio 2016 improves on its already intuitive workflow by adding exciting new features as well as speeding up the entire implant procedure."

Implant Studio is unique in that it merges surface scans and CBCT (or CT) scans to provide a best-in-class plan based on virtual tooth setups and prosthetic driven implant planning. Delivering digital insight that enables dental professionals to consider all aspects of the implant treatment, including vertical dimensions, the restorative platform and available soft tissue.

For the restorative design and production workflow steps, Implant Studio data is fully integrated with 3Shape dental lab CAD/CAM design solution, Dental System™. And to create a totally digital implant procedure, professionals can input scan data directly from, for example, 3Shape TRIOS® intraoral scanner to Implant Studio.

Article info

31-10-2016, 10:29

- Views: 1874

- Author: vipsoft

- Date: 31-10-2016, 10:29

Assyst Bullmer V 2015 20.15 Sentinel Dongle

Category: Cad Cam

Previous

Next